Gate 8-16t/H Forced Single Horizontal Concrete Twin Shaft Continuous Mixer in Compound Fertilizer Machines

Overview Fertilizer Mixer Product Description Product Detail Application fieldThis mixer is suitable for mixing various ;

Basic Info

| Model NO. | sm-035 |

| Transport Package | Standard Wooden Package |

| Specification | 180-250 m3/h |

| Trademark | GATE |

| Origin | China |

| Production Capacity | 6-22t/H |

Product Description

Fertilizer MixerProduct Description

Product Detail

| Product Name | Output | Size | Powder | Speed |

| GTM-8030D | 2-8 T/H | 4950*1650*800 | 18.5KW | 1450r/min |

| GTM-8040D | 3-10T/H | 5950*1650*800 | 18.5KW | 1450r/min |

| GTM-1050D | 6-22t/h | 226000*1900*1000 | 22KW | 1450r/min |

Application fieldThis mixer is suitable for mixing various raw materials such as compound feed, concentrated feed, additive premix, organic and compound fertilizer. The working principle is that the material enters the mixing tank, and is uniformly stirred through the spiral blades installed on a pair of oppositely rotating double shafts.

Performance parametersThe double-shaft mixer is mainly composed of housing, spiral shaft assembly, driving device, piping, cover plate, chain cover and other components. The shell is mainly welded by plate and section steel and assembled with other components, which is the support of the double-shaft mixer. The shell seal is tight, there will be no flying ash, ash leakage phenomenon.Working principle

Double shaft mixer using two symmetrical spiral shaft synchronous rotation, in conveying dry ash and other powdery materials at the same time add water stirring, uniform humidifying dry ash powdery materials, so that the humidifying material does not dry ash and does not ooze water droplets, so as to facilitate the humidifying ash loading transport or transfer to other conveying equipment Cost savingDouble-shaft stirring is faster and more uniform than single-shaft stirring. The reduction gears are matched to ensure stable mixing. Low energy consumption, high uniformity of mixed fertilizer, and less material residue. The mixing speed is uniform, and the noise during the mixing process is low. The main body of high-quality carbon steel is durable and easy to maintain.

What Can I Do For You

What Can I Do For You Pre-sale

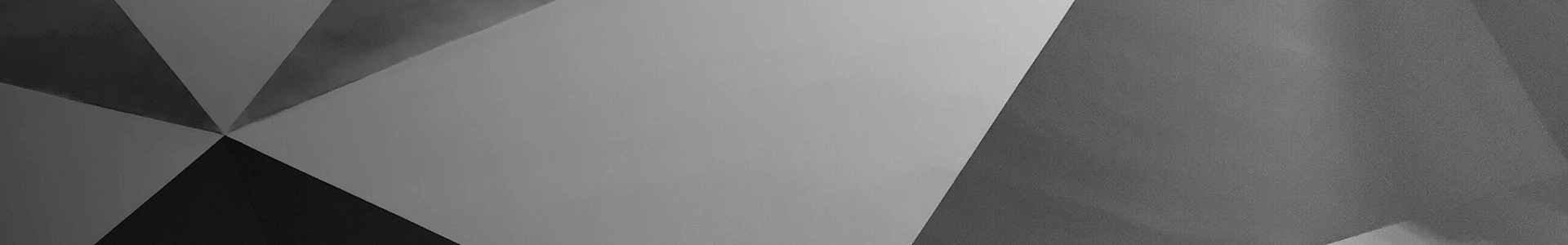

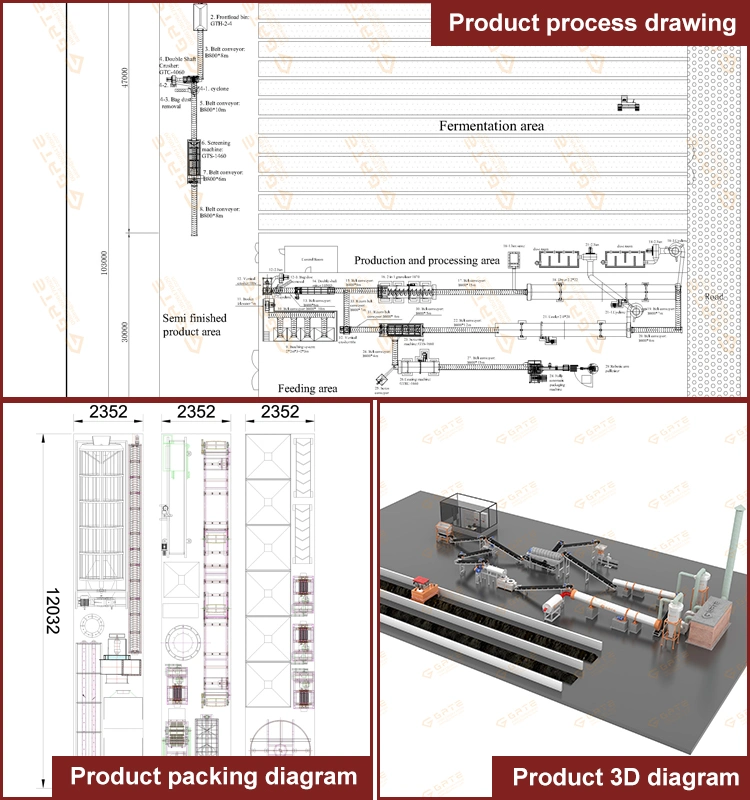

Our account manager will communicate with you the product requirements related to your machine We offer free product plans, packaging drawings and 3D renderings to save your budget We will provide our own quotation and proof of our machines We have a professional R & D department, to provide you with the most professional technical support We can make granulation experiment according to your raw materials

If you need to install, we have a professional overseas installation team We will provide you with installation drawings or a video guide for making the installation We support to provide you with free accessories within one year of purchase of machine equipment We will provide a five year warranty on important parts of the equipment

Transaction Customer

Transaction Customer

| Q: Can I use this production line to produce multi granularity particles? |

| Yes, our production line is multifunctional. We can customize ring moulds of different sizes. In this way, you can easily adjust the size of your ball. |

| Q: I know little about the fertilizer production line. How to choose the most suitable machine? |

| Just tell us your raw materials, capacity (tons / hour) and the size of the final particle product, and we will choose the machine for you according to your specific situation. |

| Q: Our workers don't know how to operate the production line. What should I do? |

| Our engineers will instruct the site workers on how to install the machines and build the workshop.And field test the production line, training workers how to operate. |

| Q: Are you a trading company or a manufacturer? |

| We have a large factory in Jiaozuo, China, covering an area of 10000 square meters. Welcome to visit. |

| Q: What's the Production Period of the Fertilizer Machine? |

| For single fertilizer machine, our production time is 7 days;and for whole fertilizer production line, our production time is no more than 30 days. |

| Q: What's the Quality Guarantee and Certifications? |

| All of our machine have passed ISO and CE certification, we can guarantee the highest quality and our warranty time is 5 years after shipment date. |

You may also like

Send inquiry

Send now